Base material: pure copper, brass copper, bronze copper

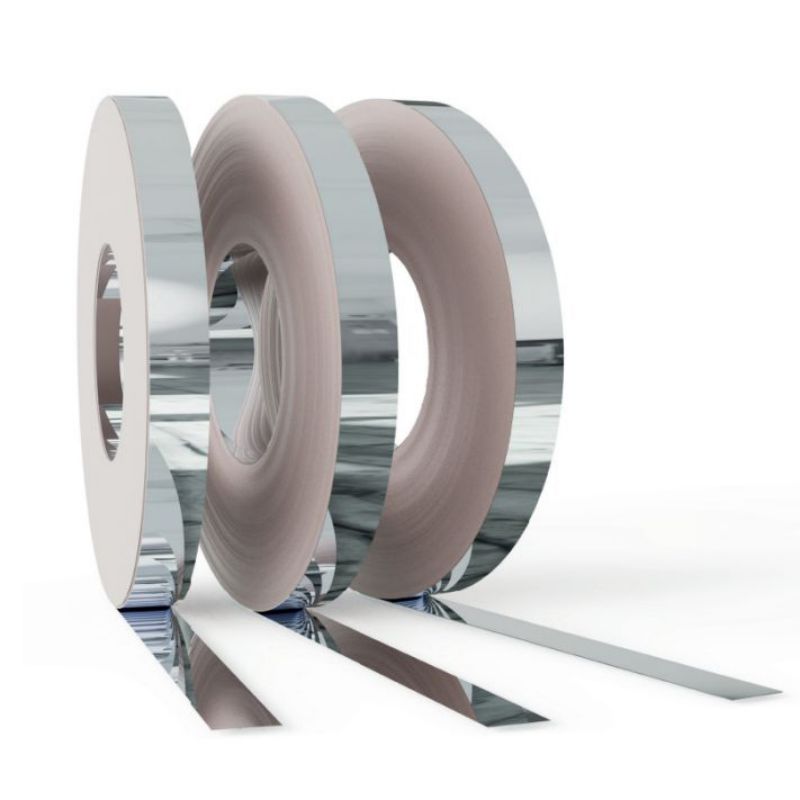

Base material thickness:0.05 to 2.0mm

Plating thickness: 0.5 to 2.0μm

Strip width:5 to 600mm

If you have any special requirements, please without hesitate to contact us, our professional team always be here for you.

Good oxidation resistance: the specially treated surface can effectively prevent oxidation and corrosion.

Good corrosion resistance: After the surface is plated with tin, it can effectively resist chemical corrosion, especially in high temperature, high humidity and high corrosive environments.

Excellent electrical conductivity: As a high-quality conductive material, copper drop has excellent electrical conductivity, and anti-oxidation copper (tinned) has been specially treated on this basis to make the electrical conductivity more stable.

High surface flatness: Anti-oxidation copper foil (tin-plated) has high surface flatness, which can meet the requirements of high-precision circuit board processing.

Easy installation: anti-oxidation copper foil (tin-plated) can be easily pasted on the surface of the circuit board, and the installation is simple and convenient

Electronic component carrier: tinned copper foil can be used as a carrier for electronic components, and the electronic components in the circuit are pasted on the surface, thereby reducing the resistance between the electronic components and the substrate.

Shielding function: Tinned copper foil can be used to make electromagnetic wave shielding layer, so as to shield the interference of radio waves.

Conductive function: tinned copper foil can be used as a conductor to transmit current in the circuit.

Corrosion resistance function: tinned copper foil can resist corrosion, thus prolonging the service life of the circuit.

Gold-plated layer - to improve the electrical conductivity of electronic products

Gold plating is a treatment method of electroplated copper foil, which can form a metal layer on the surface of copper foil. This treatment can improve the conductivity of copper foil, making it widely used in high-end electronic products. Especially in the connection and conduction of the internal structural parts of electronic equipment such as mobile phones, tablets, and computers, gold-plated copper foil exhibits excellent performance.

Nickel-plated layer - to achieve signal shielding and anti-electromagnetic interference

Nickel plating is another common electroplated copper foil treatment. By forming a nickel layer on the surface of copper foil, the signal shielding and anti-electromagnetic interference functions of electronic products can be realized. Electronic devices with communication functions such as mobile phones, computers, and navigators all require signal shielding, and nickel-plated copper foil is an ideal material to meet this demand.

Tin-plated layer - improve heat dissipation and soldering performance

Tin plating is another treatment method of electroplated copper foil, which forms a tin layer on the surface of copper foil. This treatment can not only improve the electrical conductivity of the copper foil, but also improve the thermal conductivity of the copper foil. Modern electronic equipment, such as mobile phones, computers, televisions, etc., require good heat dissipation performance, and tinned copper foil is an ideal choice to meet this demand.