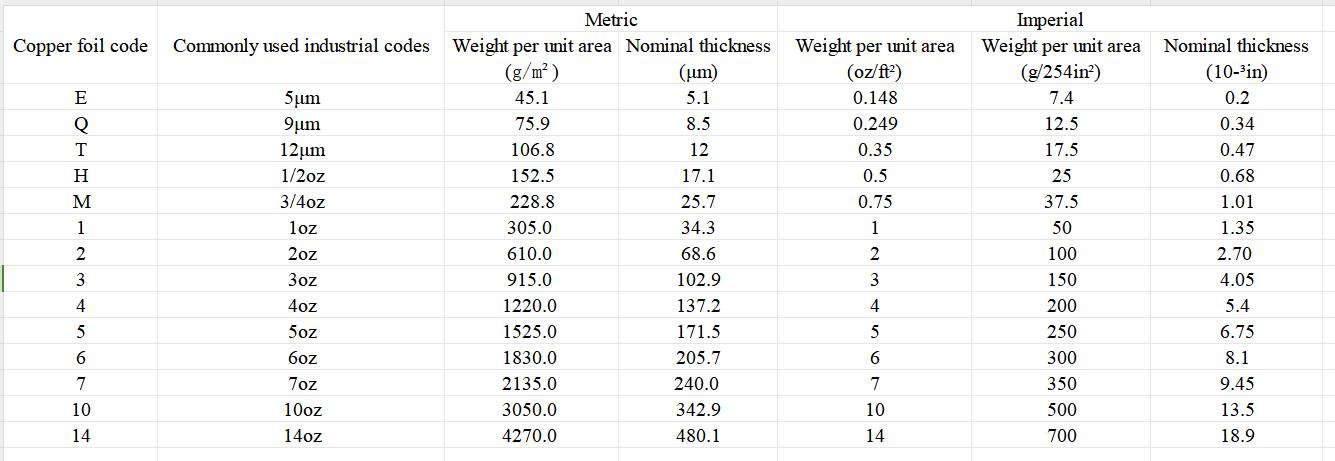

Thickness and weight of copper foil(Excerpted from IPC-4562A)

The copper thickness of PCB copper-clad board is usually expressed in imperial ounces (oz), 1oz=28.3g, such as 1/2oz, 3/4oz, 1oz, 2oz. For example, the area mass of 1oz/ft² is equivalent to 305 g/㎡ in metric units. , converted by copper density (8.93 g/cm²), equivalent to a thickness of 34.3um.

The definition of copper foil "1/1": a copper foil with an area of 1 square foot and a weight of 1 ounce; spread 1 ounce of copper evenly on a plate with an area of 1 square foot.

Thickness and weight of copper foil

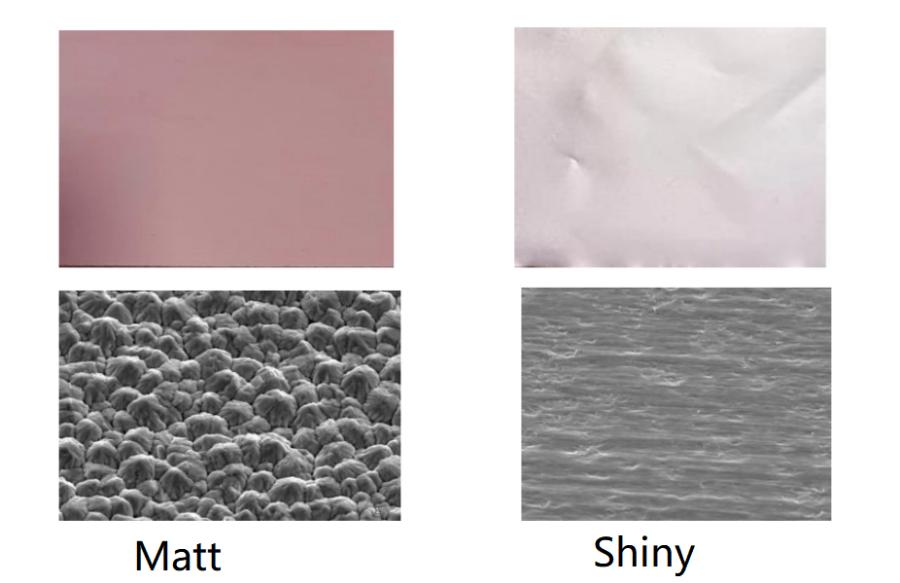

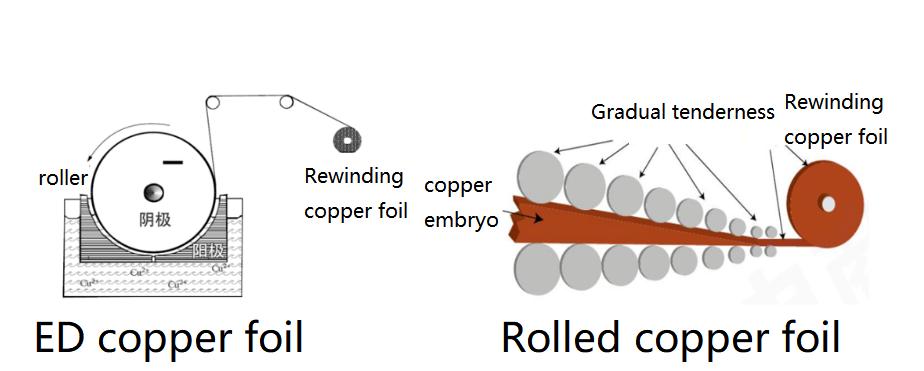

☞ED, Electrodeposited copper foil (ED copper foil), refers to copper foil made by electrodeposition. The manufacturing process is an electrolysis process. Electrolysis equipment generally uses a surface roller made of titanium material as the cathode roller, high-quality soluble lead-based alloy or insoluble titanium-based corrosion-resistant coating as the anode, and sulfuric acid is added between the cathode and anode. Copper electrolyte, under the action of direct current, has metal copper ions adsorbed on the cathode roller to form electrolytic original foil. As the cathode roller continues to rotate, the generated original foil is continuously adsorbed and peeled off on the roller. Then it is washed, dried, and wound into a roll of raw foil. The copper foil purity is 99.8%.

☞RA, Rolled annealed copper foil, is extracted from copper ore to produce blister copper, which is smelted, processed, electrolytically purified, and made into copper ingots about 2mm thick. The copper ingot is used as the base material, which is pickled, degreased, and hot-rolled and rolled (in the long direction) at temperatures above 800°C for many times. Purity 99.9%.

☞HTE, high temperature elongation electrodeposited copper foil, is a copper foil that maintains excellent elongation at high temperatures (180°C). Among them, the elongation of copper foil with thickness of 35μm and 70μm at high temperature (180℃) should be maintained at more than 30% of the elongation at room temperature. Also called HD copper foil (high ductility copper foil).

☞DST, double side treatment copper foil, roughens both the smooth and rough surfaces. The current main purpose is to reduce costs. Roughening the smooth surface can save the copper surface treatment and browning steps before lamination. It can be used as the inner layer of copper foil for multi-layer boards, and does not need to be browned (blackened) before laminating the multi-layer boards. The disadvantage is that the copper surface must not be scratched, and it is difficult to remove if there is contamination. At present, the application of double-sided treated copper foil is gradually decreasing.

☞UTF, ultra thin copper foil, refers to copper foil with a thickness less than 12μm. The most common ones are copper foils below 9μm, which are used on printed circuit boards for manufacturing fine circuits. Because extremely thin copper foil is difficult to handle, it is generally supported by a carrier. Types of carriers include copper foil, aluminum foil, organic film, etc.

| Copper foil code | Commonly used industrial codes | Metric | Imperial | |||

| Weight per unit area (g/m²) |

Nominal thickness (μm) |

Weight per unit area (oz/ft²) |

Weight per unit area (g/254in²) |

Nominal thickness (10-³in) |

||

| E | 5μm | 45.1 | 5.1 | 0.148 | 7.4 | 0.2 |

| Q | 9μm | 75.9 | 8.5 | 0.249 | 12.5 | 0.34 |

| T | 12μm | 106.8 | 12 | 0.35 | 17.5 | 0.47 |

| H | 1/2oz | 152.5 | 17.1 | 0.5 | 25 | 0.68 |

| M | 3/4oz | 228.8 | 25.7 | 0.75 | 37.5 | 1.01 |

| 1 | 1oz | 305.0 | 34.3 | 1 | 50 | 1.35 |

| 2 | 2oz | 610.0 | 68.6 | 2 | 100 | 2.70 |

| 3 | 3oz | 915.0 | 102.9 | 3 | 150 | 4.05 |

| 4 | 4oz | 1220.0 | 137.2 | 4 | 200 | 5.4 |

| 5 | 5oz | 1525.0 | 171.5 | 5 | 250 | 6.75 |

| 6 | 6oz | 1830.0 | 205.7 | 6 | 300 | 8.1 |

| 7 | 7oz | 2135.0 | 240.0 | 7 | 350 | 9.45 |

| 10 | 10oz | 3050.0 | 342.9 | 10 | 500 | 13.5 |

| 14 | 14oz | 4270.0 | 480.1 | 14 | 700 | 18.9 |