OEM/ODM Supplier Copper Square Bar - Customize Copper Rod – ZHJ Detail:

1. Extrusion -(rolling) – stretching -(annealing) – finishing – finished products.

2. Continuous casting (lead up, horizontal or wheeled, tracked, impregnated)-(rolling)- stretching -(annealing)- finishing – finished products.

3. Continuous extrusion – stretching -(annealing) – finishing – finished products.

|

Material For Copper Rod |

|

| Copper | C11000, C10200, C12000, C12200 |

| Brass | C21000, C22000, C23000, C24000, C26000, C26200, C26800, C27000, C27200, C28000 |

| Bronze | Phosphor Bronze, Tin Bronze, Aluminum Bronze, Silicon Bronze, Manganese Bronze. |

| Copper nickel alloy | Zinc Copper Nickel, Iron Copper Nickel, etc. |

Copper is a relatively pure copper, generally can be approximated as pure copper. It’s better conductivity and plasticity, but the strength and hardness is ideal.

According to the composition, China’s copper production materials can be divided into four categories: ordinary copper, oxygen-free copper, oxygenated copper and special copper which increase a few alloying elements (such as arsenic copper, tellurium copper, silver copper) . Copper’s electrical and thermal conductivity is second only to silver, and it is widely used in the manufacture of electrically and thermally conductive devices.

Brass rod is a rod shaped object made of copper and zinc alloy, named for its yellow color. Brass rod has good mechanical properties and wear resistance. It is mainly used in the manufacture of precision instruments, ship parts, auto parts, medical accessories, electrical accessories and all kinds of mechanical auxiliary materials, automotive synchronizer tooth rings.

Bronze rod has good electrical and thermal conductivity, good processing and forming performance, and it is widely used in high temperature conductive wear-resistant parts of electrical equipment. Such as motor fairings, collector rings, high temperature switches, electrodes of welding machines, rollers, grippers etc.

Copper nickel alloy rod is a copper alloy with nickel as the main alloying element, which is a continuous solid solution formed by Cu and Ni. Ordinary white copper rod has good corrosion resistance, medium strength, high plasticity and good electrical properties. It can be cold and hot pressure processing. In addition to being used as a structural material, it is also an important high resistance and thermocouple alloy.

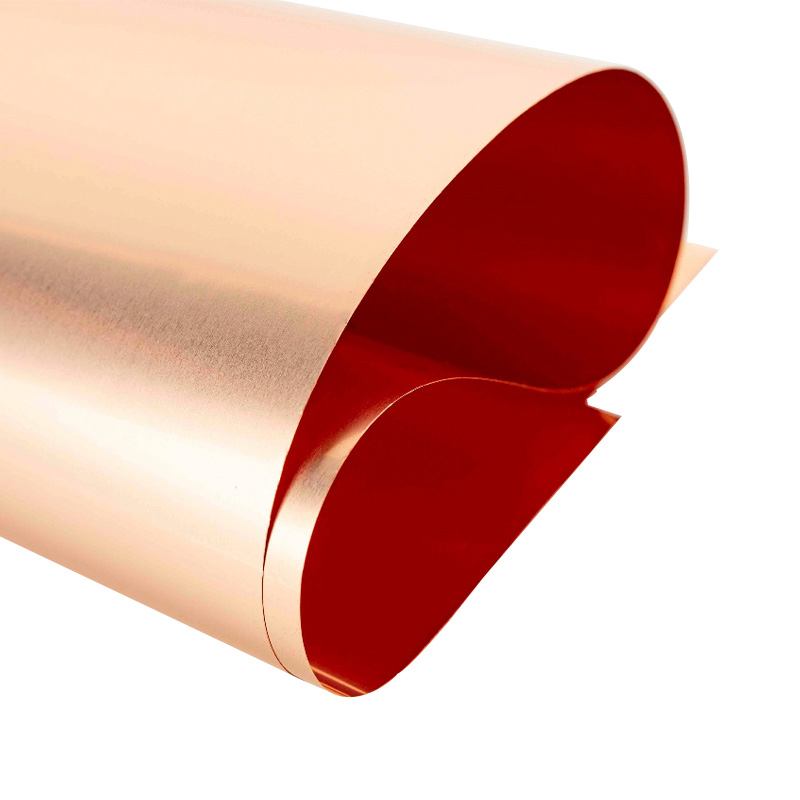

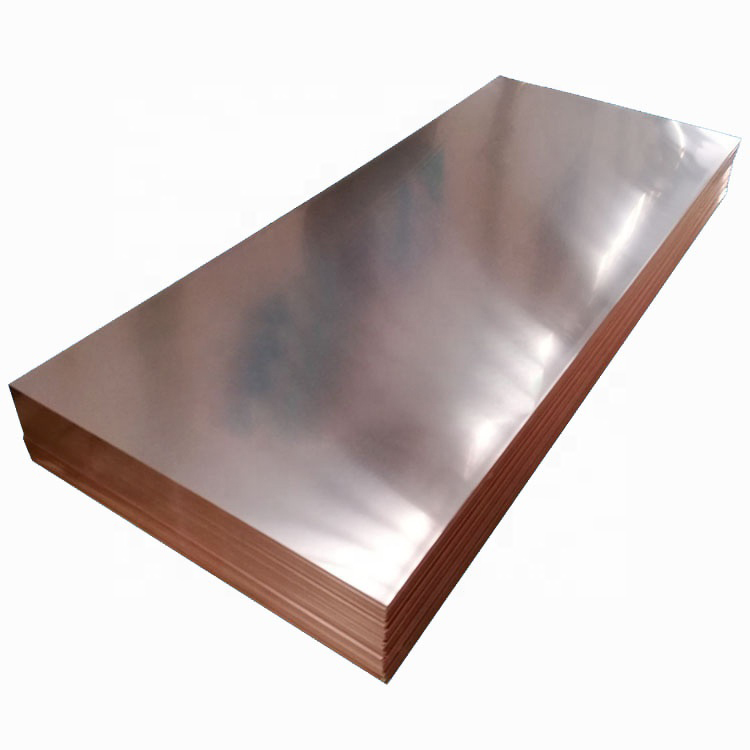

Product detail pictures:

Related Product Guide:

We're convinced that with joint endeavours, the business between us will bring us mutual benefits. We are able to guarantee you products high quality and competitive value for OEM/ODM Supplier Copper Square Bar - Customize Copper Rod – ZHJ, The product will supply to all over the world, such as: Czech republic, Guatemala, Pakistan, We have top engineers in these industries and an efficient team in the research. What is more, we have our own archives mouths and markets in China at low cost. Therefore, we can meet different inquiries from different clients. Please find our website to check more information from our products.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.