OEM Factory For Brazing Copper Sheet - Copper Nickel Alloy Plate/White Copper Plate – ZHJ Detail:

Ordinary White Copper

White copper is a copper-based alloy with nickel as the main additive element. It is silver-white and has metallic luster, so it is named white copper.When nickel is melted into red copper and the content exceeds 16%, the color of the resulting alloy becomes as white as silver. The higher the nickel content, the whiter the color. The nickel content in white copper is generally 25%.

Pure copper plus nickel can significantly improve strength, corrosion resistance, hardness, electrical resistance and pyroelectric properties, and reduce the temperature coefficient of resistivity. Therefore, compared with other copper alloys, cupronickel has exceptionally good mechanical and physical properties, good ductility, high hardness, beautiful color, corrosion resistance, and deep drawing properties. It is widely used in shipbuilding, petrochemicals, electrical appliances, instruments, medical equipment, Daily necessities, handicrafts and other fields, and is also an important resistance and thermocouple alloy. The disadvantage of cupronickel is that the main added element-nickel is a scarce strategic material and is relatively expensive.

Complex White Copper

Iron Copper Nickel:Grades are T70380,T71050,T70590,T71510. The amount of iron added in white copper should not exceed 2% to prevent corrosion and cracking.

Manganese Copper Nickel:Grades are T71620, T71660. Manganese white copper has a low temperature coefficient of resistance, can be used in a wide temperature range, has good corrosion resistance, and has good workability.

Zinc Copper Nickel:Zinc white copper has excellent comprehensive mechanical properties, excellent corrosion resistance, good cold and hot processing formability, easy cutting, and can be made into wires, bars and plates.It is used to manufacture precision parts in the fields of instruments, meters, medical equipment, daily necessities and communications.

Aluminum Copper Nickel:It is an alloy formed by adding aluminum to a copper-nickel alloy with a density of 8.54.The performance of the alloy is related to the ratio of nickel and aluminum in the alloy. When Ni:Al=10:1, the alloy has the best performance. Commonly used aluminum cupronickel are Cu6Ni1.5Al, Cul3Ni3Al, etc., which are mainly used for various high-strength corrosion-resistant parts in shipbuilding, electric power, chemical industry and other industrial sectors.

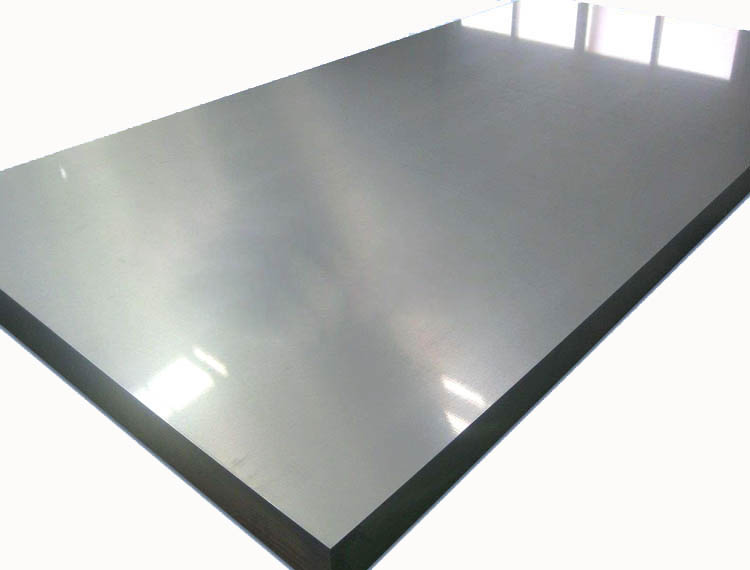

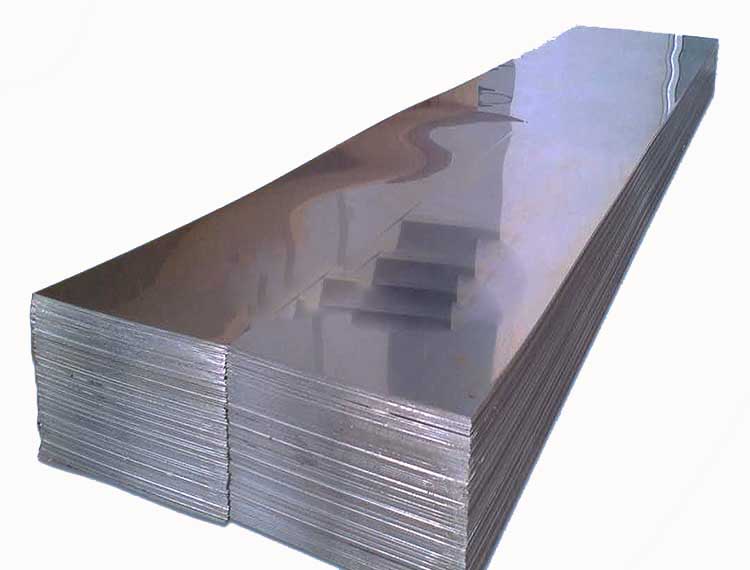

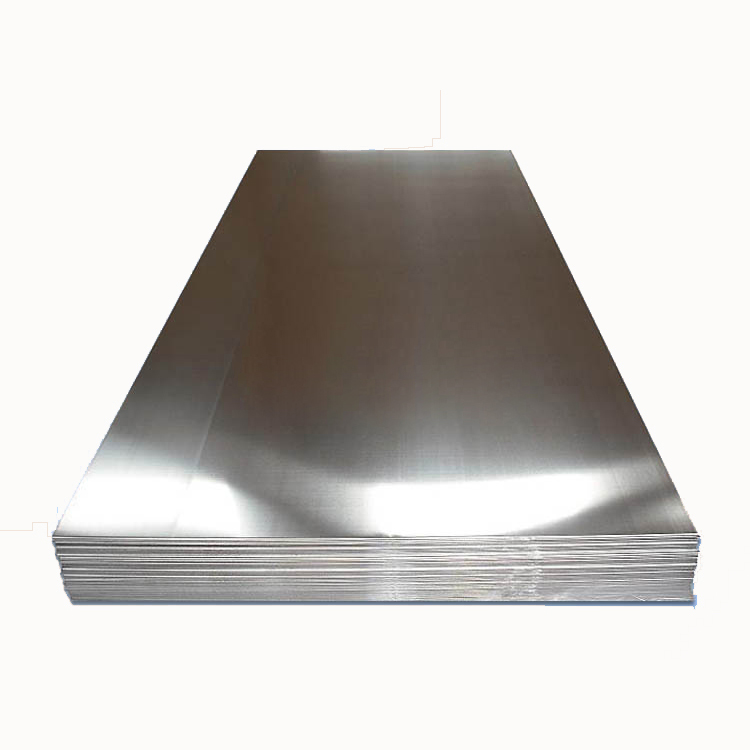

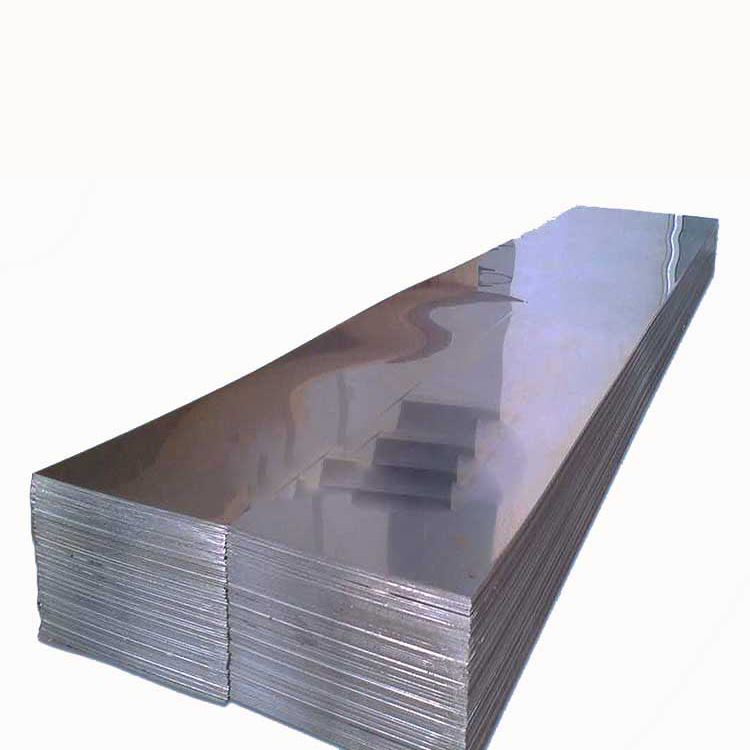

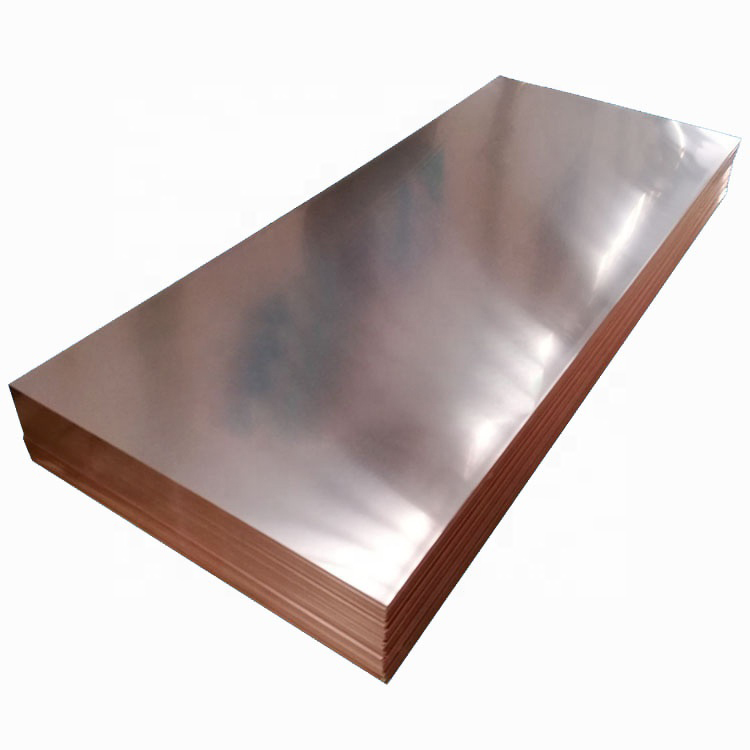

Product detail pictures:

Related Product Guide:

To create much more benefit for consumers is our company philosophy; customer growing is our working chase for OEM Factory For Brazing Copper Sheet - Copper Nickel Alloy Plate/White Copper Plate – ZHJ, The product will supply to all over the world, such as: Cancun, Cambodia, Cyprus, Our company insists on the principle of "Quality First, Sustainable Development", and takes "Honest Business, Mutual Benefits" as our developable goal. All members sincerely thank all old and new customers' support. We will keep working hard and offering you the highest-quality products and service.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.

-

2022 Latest Design Copper Door Kick Plate - Co...

-

PriceList For Brushed Bronze Sheet Metal - Cop...

-

OEM/ODM Factory 10 Oz Copper Bar - Customize C...

-

High Definition Decorative Bronze Sheet Metal -...

-

OEM Supply Copper Strip Coil - Customized High...

-

2022 Good Quality 99.99% Pure Copper Sheet - B...