OEM China Copper Bus Bar Coating - Customize Copper Rod – ZHJ Detail:

1. Extrusion -(rolling) – stretching -(annealing) – finishing – finished products.

2. Continuous casting (lead up, horizontal or wheeled, tracked, impregnated)-(rolling)- stretching -(annealing)- finishing – finished products.

3. Continuous extrusion – stretching -(annealing) – finishing – finished products.

|

Material For Copper Rod |

|

| Copper | C11000, C10200, C12000, C12200 |

| Brass | C21000, C22000, C23000, C24000, C26000, C26200, C26800, C27000, C27200, C28000 |

| Bronze | Phosphor Bronze, Tin Bronze, Aluminum Bronze, Silicon Bronze, Manganese Bronze. |

| Copper nickel alloy | Zinc Copper Nickel, Iron Copper Nickel, etc. |

Copper is a relatively pure copper, generally can be approximated as pure copper. It’s better conductivity and plasticity, but the strength and hardness is ideal.

According to the composition, China’s copper production materials can be divided into four categories: ordinary copper, oxygen-free copper, oxygenated copper and special copper which increase a few alloying elements (such as arsenic copper, tellurium copper, silver copper) . Copper’s electrical and thermal conductivity is second only to silver, and it is widely used in the manufacture of electrically and thermally conductive devices.

Brass rod is a rod shaped object made of copper and zinc alloy, named for its yellow color. Brass rod has good mechanical properties and wear resistance. It is mainly used in the manufacture of precision instruments, ship parts, auto parts, medical accessories, electrical accessories and all kinds of mechanical auxiliary materials, automotive synchronizer tooth rings.

Bronze rod has good electrical and thermal conductivity, good processing and forming performance, and it is widely used in high temperature conductive wear-resistant parts of electrical equipment. Such as motor fairings, collector rings, high temperature switches, electrodes of welding machines, rollers, grippers etc.

Copper nickel alloy rod is a copper alloy with nickel as the main alloying element, which is a continuous solid solution formed by Cu and Ni. Ordinary white copper rod has good corrosion resistance, medium strength, high plasticity and good electrical properties. It can be cold and hot pressure processing. In addition to being used as a structural material, it is also an important high resistance and thermocouple alloy.

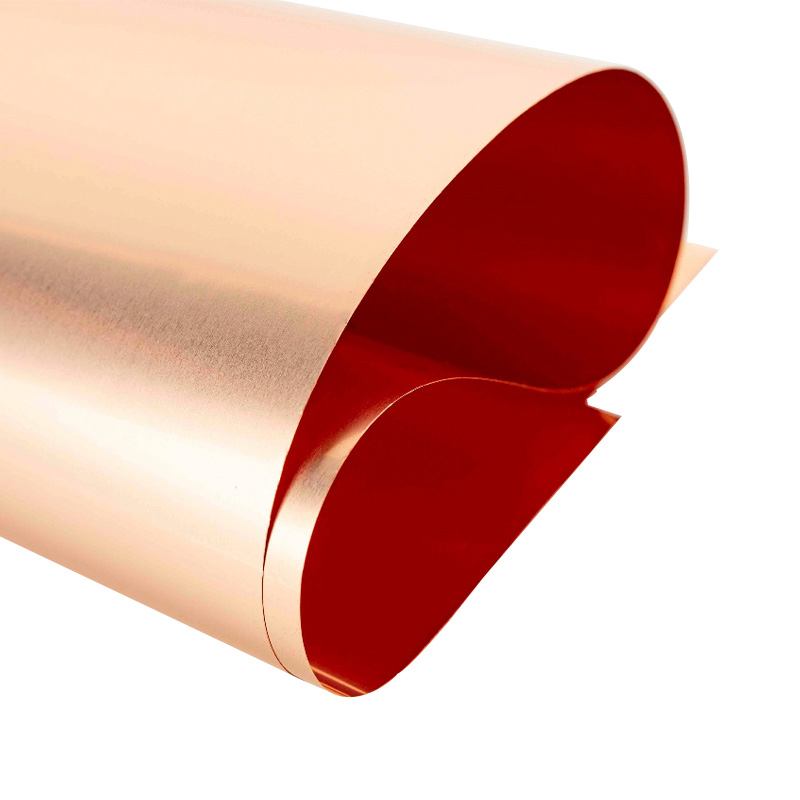

Product detail pictures:

Related Product Guide:

With our excellent administration, potent technical capability and strict top quality control technique, we go on to provide our consumers with trusted quality, reasonable price ranges and fantastic providers. We intention at becoming one among your most trusted partners and earning your fulfillment for OEM China Copper Bus Bar Coating - Customize Copper Rod – ZHJ, The product will supply to all over the world, such as: Azerbaijan, Brazil, Greenland, With the development and enlargement of mass clients abroad, now we have set up cooperative relationships with many major brands. We have our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the "quality first, customer first, We are provideing high-quality, low-cost products and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.

-

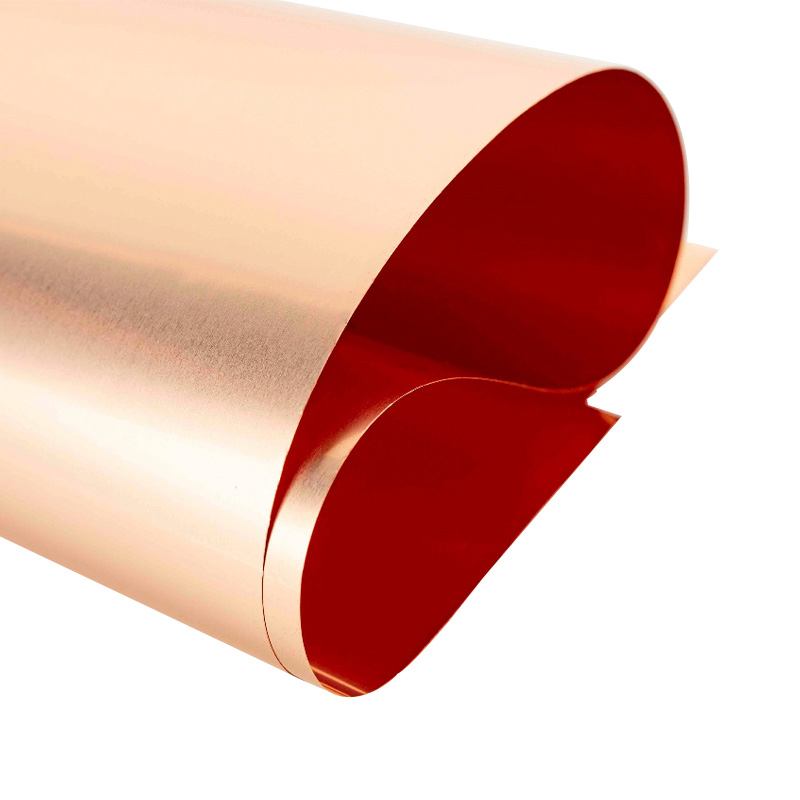

Low MOQ For Copper Foil Patina - Customize Hig...

-

Top Quality Conductive Copper Foil - Customize...

-

2022 New Style Ra Copper Foil - Customize High...

-

Factory Best Selling Brass Plate Sheet For Manu...

-

Big Discounting Decorative Brass Sheet Metal -...

-

Factory Free Sample Battery Collector 10um Copp...