As the name suggests, naval brass is a copper alloy suitable for marine scenes. Its main components are copper (Cu), zinc (Zn) and tin (Sn). This alloy is also called tin brass. The addition of tin can effectively inhibit the dezincification of brass and improve the corrosion resistance.

In the marine environment, a thin and dense protective film will form on the surface of copper alloy, which is mainly composed of copper and tin oxides and some complex salts. This protective layer can effectively prevent seawater from corroding the inside of the alloy and slow down the corrosion rate. Compared with ordinary brass, the corrosion rate of naval brass can be reduced several times.

Common naval copper alloys include C44300 (HSn70-1/T45000), which has the following composition:

Copper (Cu): 69.0% - 71.0%

Zinc (Zn): Balance

Tin (Sn): 0.8% - 1.3%

Arsenic (As): 0.03% - 0.06%

Other alloying elements: ≤0.3%

Arsenic can inhibit dezincification corrosion and further improve the corrosion resistance of the alloy.C44300 has good mechanical properties and is used to make heat exchangers and conduits that come into contact with corrosive liquids. It is particularly widely used in inland thermal power plants to make high-strength, corrosion-resistant heat exchanger condenser tubes. Recent studies have shown that adding trace amounts of boron, nickel and other elements to C44300 can better improve the corrosion resistance. C44300 has a tendency to stress corrosion cracking, and cold-processed pipes must be subjected to stress relief low-temperature annealing. C44300 is prone to cracking during hot pressing, and the content of impurities must be strictly controlled.

C46400 (HSn62-1/T46300) is also a naval brass with a lower copper content. Its main components are as follows:

Cu: 61-63%

Zn: 35.4-38.3%

Sn: 0.7-1.1%

Fe: ≤0.1%

Pb: ≤0.1%

C46400 is cold brittle during cold working and is only suitable for hot pressing. It has good machinability and is easy to weld and braze, but has a tendency to corrode and crack (seasonal crack). C46400 tin brass is used in the shipbuilding industry to manufacture parts that come into contact with seawater, gasoline, etc.

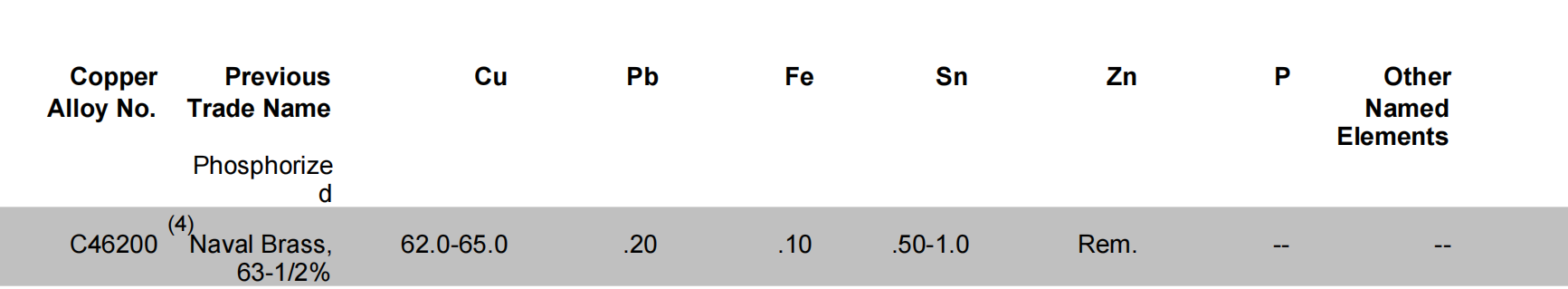

Due to the slight differences between the standards, as a Chinese brass strip/brass rod/brass plate supplier, we often use HSn62-1 to replace C46400/C46200/C4621. The copper content of C46200 is slightly higher.

C48500 (QSn4-3) is a high-lead naval brass. The lead content is higher than the two grades mentioned above. Its main components are as follows:

· Copper (Cu): 59.0%~62.0%

· Lead (Pb): 1.3%~2.2%

· Iron (Fe): ≤0.10%

· Tin (Sn): 0.5%~1.0%

· Zinc (Zn): Balance

· Phosphorus (P): 0.02%~0.10%

It has good elasticity, wear resistance and anti-magnetism. It is suitable for pressure processing in cold and hot states. It is easy to weld and braze. It has good machinability and good corrosion resistance in the atmosphere, fresh water and sea water. It is often used in various elastic components, pipe fittings, chemical equipment, wear-resistant parts and anti-magnetic parts.

As a reliable brass and copper sheet manufacturer, CNZHJ often stock common size naval brass plates. Also support customization for mass production. Please send inquiry to : info@cnzhj.com

Post time: Jan-02-2025