Bimetallic materials make efficient use of valuable copper. As global copper supplies decrease and demand grows, conserving copper is critical.

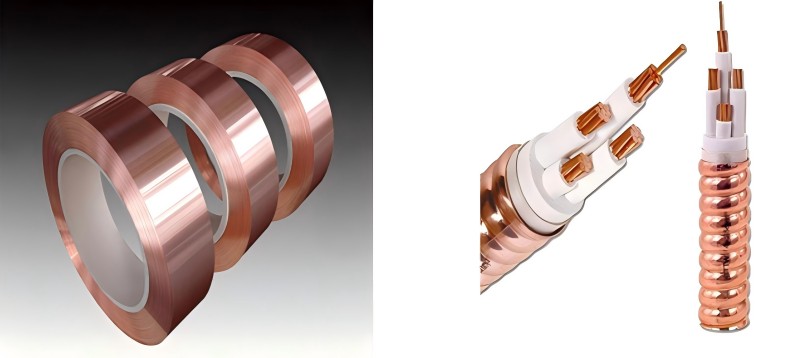

Copper clad aluminum wire and cable refers to a wire and cable that uses aluminum core wire instead of copper as the main body and is covered with a certain proportion of copper layer on the outside.

Copper clad aluminum wire adopts the coating welding manufacturing technology to concentrically cover the outer surface of the core wire such as aluminum rod or steel wire, and form a strong metallurgical bond between the copper layer and the core wire, so that the two different metal materials are combined into an inseparable whole.

Copper clad aluminum uses oxygen free copper strip. Oxygen-free copper is pure copper that does not contain oxygen or any deoxidizer residue. But in fact, it still contains very trace amounts of oxygen and some impurities. According to the standard, the oxygen content is not more than 0.003%, the total impurity content is not more than 0.05%, and the purity of copper is greater than 99.95%.

Commonly used grades of copper strips for copper clad aluminum are C10200 Oxygen Free (OF) Copper, C10300 Oxygen Free-Extra Low Phosphorus (OFXLP) Copper, C11000 Low Oxygen (LO-OX) ETP Copper and C12000 Deoxidized Low Phosphorus (DLP) Copper.

Post time: Sep-05-2024