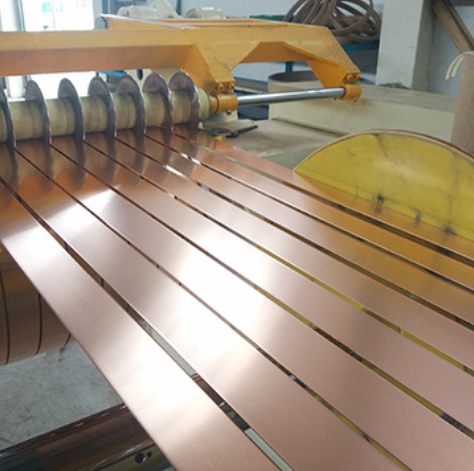

Beryllium copper strips, known for their remarkable properties, are widely utilized in numerous industries due to their high strength, elasticity, hardness, and wear resistance. Among them, grades C17200, C17510, and C17530 stand out with distinct chemical compositions, mechanical characteristics, and applications.

Grade C17200 Beryllium Copper:

- Mold Manufacturing: C17200 beryllium copper is widely used in the manufacture of injection molds and high-pressure blow molding molds. Its high strength and excellent thermal conductivity enable rapid cooling of the molds, thus improving production efficiency and shortening the injection molding cycle.

- Electronics Industry: Due to its high electrical conductivity, non-magnetic properties, and good wear resistance, C17200 beryllium copper is ideal for the manufacture of molds, tools, and high-thermal conductivity bearings that are not susceptible to magnetic interference. These characteristics make it excellent for electronic equipment requiring precise control and high reliability.

- Marine Engineering: C17200 beryllium copper’s excellent corrosion resistance, particularly in seawater and sulfuric acid media, makes it the preferred material for key components such as underwater cable repeater structures.

Grade C17510 Beryllium Copper:

- Mold Components: C17510 beryllium copper is widely used in the manufacture of inserts and cores for injection molds or steel molds. It can effectively reduce the temperature in heat-concentrated areas, simplifying or eliminating the need for cooling water channel design.

- Electrode Manufacturing: Its high strength and high electrical conductivity make it highly regarded in industrial applications such as aerospace, automotive, electronics, power, and metallurgy.

- Corrosive Environments: C17510 beryllium copper exhibits excellent corrosion resistance in seawater, with a corrosion rate of (1.1-1.4)×10⁻²mm/year and a corrosion depth of (10.9-13.8)×10⁻³mm/year. It can maintain its strength and elongation after corrosion and remain effective for over 40 years in seawater.

Grade C17530 Beryllium Copper:

- Though specific application scenarios for C17530 beryllium copper may vary, it is tailored for specialized applications due to its unique mechanical properties. These could include high-precision components in aerospace, electronics, or other high-tech fields where performance and reliability are crucial.

In summary, each grade of beryllium copper strips excels in specific application scenarios due to their unique blend of mechanical and electrical properties. Grade C17200 stands out in mold manufacturing, electronics, and marine engineering; Grade C17510 shines in mold components, electrode manufacturing, and corrosive environments; while Grade C17530 is tailored for specialized applications requiring high performance.

Post time: Feb-19-2025