Performance characteristics:

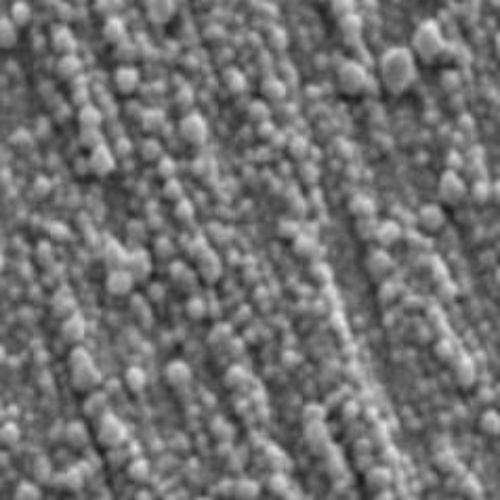

Compared with single-sided matte and double-sided matte lithium copper foil, when double-sided shiny copper foil is bonded with the negative material, the contact area increases exponentially, which can significantly reduce the contact resistance between the negative fluid collector and the negative material, and improve the symmetry of the negative electrode sheet structure of the lithium ion battery. At the same time, the double-sided shiny lithium copper foil has good thermal expansion resistance, and the negative electrode sheet is not easy to break during the charge and discharge process of the battery which can extend the battery life.

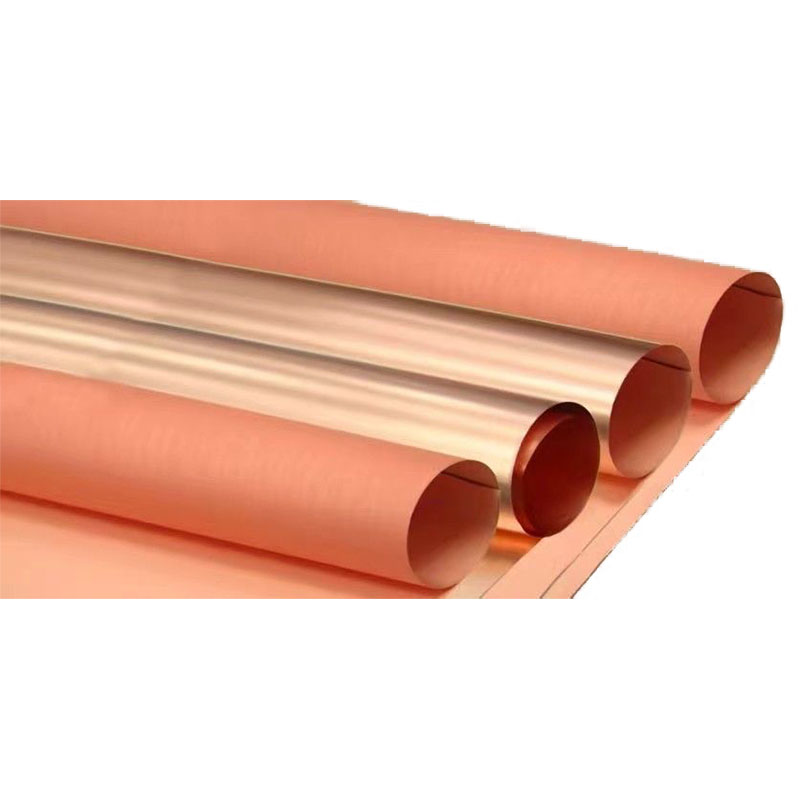

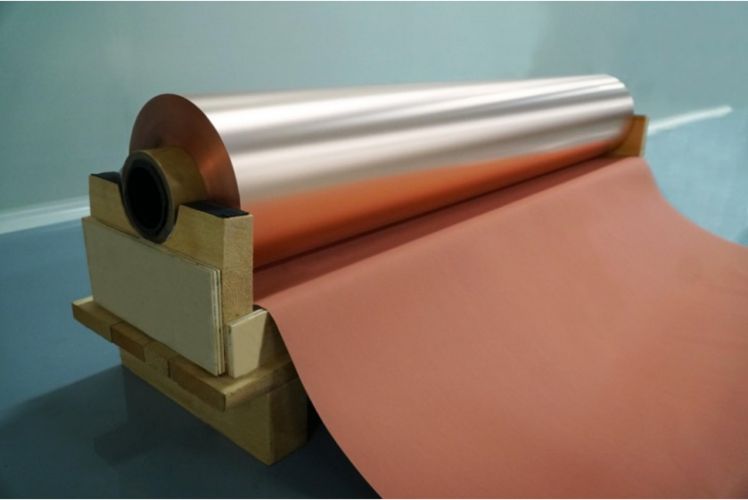

Specifications: provide nominal thickness 8~35um in different width of double-sided shiny lithium copper foil.

Application: Used as a negative carrier and fluid collector for lithium-ion batteries.

Properties: double-sided structure symmetry, metal density close to the theoretical density of copper, the surface profile is extremely low, high elongation and high tensile strength. See below date sheet.

| Nominal Thickness |

Area weight g/m2 |

Elongation% |

Roughness μm |

Matte side |

Shiny side |

| R.T.(25°C) |

R.T.(25°C) |

| 6μm |

50-55 |

≥30 |

≥3 |

≤3.0 |

≤0.43 |

| 8μm |

70-75 |

≥30 |

≥5 |

≤3.0 |

≤0.43 |

| 9μm |

95-100 |

≥30 |

≥5 |

≤3.0 |

≤0.43 |

| 12μm |

105-100 |

≥30 |

≥5 |

≤3.0 |

≤0.43 |

| 15μm |

128-133 |

≥30 |

≥8 |

≤3.0 |

≤0.43 |

| 18μm |

157-163 |

≥30 |

≥8 |

≤3.0 |

≤0.43 |

| 20μm |

175-181 |

≥30 |

≥8 |

≤3.0 |

≤0.43 |

| 25μm |

220-225 |

≥30 |

≥8 |

≤3.0 |

≤0.43 |

| 30μm |

265-270 |

≥30 |

≥9 |

≤3.0 |

≤0.43 |

| 35μm |

285-290 |

≥30 |

≥9 |

≤3.0 |

≤0.43 |