Good User Reputation For Copper Backing Plate - Bronze Plates – Rich Stock, Fast Delivery – ZHJ Detail:

Phosphor Bronze

Phosphor bronze, or tin bronze, is a bronze alloy that contains a mixture of copper with 0.5-11% tin and 0.01-0.35% phosphorous.

Phosphor bronze alloys are primarily used for electrical products because they have superb spring qualities, high fatigue resistance, excellent formability, and high corrosion resistance. The addition of tin increases the corrosion resistance and strength of the alloy. The phosphor increases the wear resistance and stiffness of the alloy.Other uses include corrosion resistant bellows, diaphragms, spring washers, bushings, bearings, shafts, gears, thrust washers, and valve parts.

Tin Bronze

Tin bronze is strong and hard and has very high ductility. This combination of properties gives them a high load-carrying capacity, good wear resistance, and the ability to withstand pounding.

Tin’s principal function is to strengthen these bronze alloys. Tin bronze is strong and hard and has very high ductility. This combination of properties gives them a high load-carrying capacity, good wear resistance, and the ability to withstand pounding. The alloys are noted for their corrosion resistance in seawater and brines. Common industrial applications include fittings used to 550 F, gears, bushings, bearings, pump impellers, and many more.

Aluminum Bronze

Aluminum bronze alloys are used for their combination of high strength and excellent corrosion and wear resistance. C95400 aluminum bronze is a popular cast aluminum bronze with high-strength properties and excellent resistance to wear and corrosion. Although this alloy is supplied in the cast condition, it can be heat-treated to enhance its mechanical properties for more demanding applications.

Aluminum bronze alloys are used in marine hardware, shafts, and pump and valve components for handling seawater, sour mine waters, non-oxidizing acids, and industrial process fluids. They are also used in applications such as heavy duty sleeve bearings and machine tool ways. Aluminum bronze castings have exceptional corrosion resistance, high strength, toughness, and wear resistance. Not to mention their good casting and welding characteristics.

Beryllium Bronze

One of the highest strength copper based alloys available on the market today is beryllium copper, also known as spring copper or beryllium bronze. The commercial grades of beryllium copper contain 0.4 to 2.0 percent beryllium. The small ratio of beryllium to copper creates a family of high copper alloys with strength as high as alloy steel.The principle characteristics of these alloys are their excellent response to precipitation-hardening treatments, excellent thermal conductivity, and resistance to stress relaxation.

Beryllium copper and its variety of alloys are utilized in very specific and often tailor-made applications such as oilfield tools, aerospace landing gears, robotic welding, and mold making applications. Additional non-magnetic properties make it ideal for down-hole wire line tools. These specific applications are the reason this copper is known as spring copper and other various names.

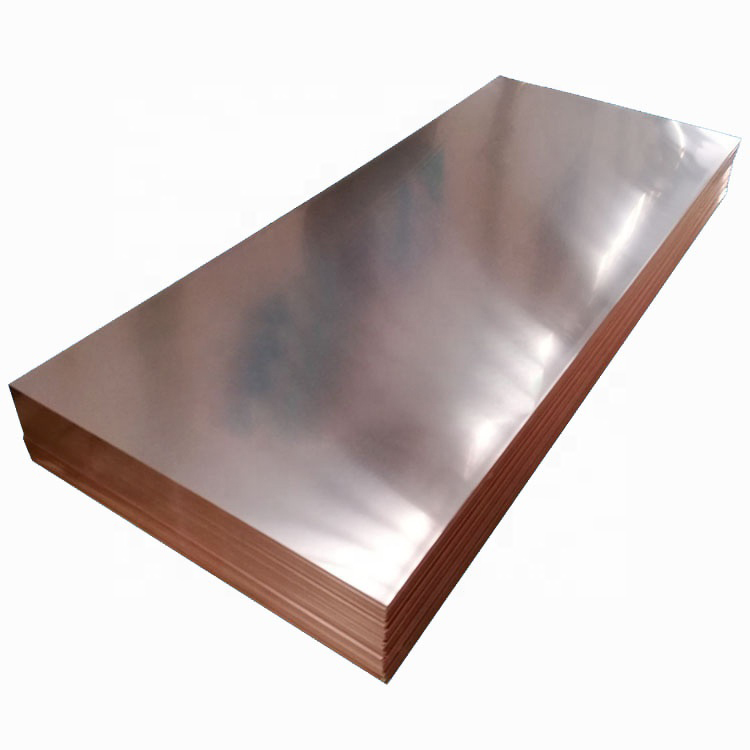

As a manufacturer with 15 years of export and production experience, “CNZHJ” has a variety of shapes and sizes available to meet the needs of your project, including sheets, strips, plates, wires, rods and bars. At the same time, we can also provide different grades of bronze with different compositions according to your requirements.

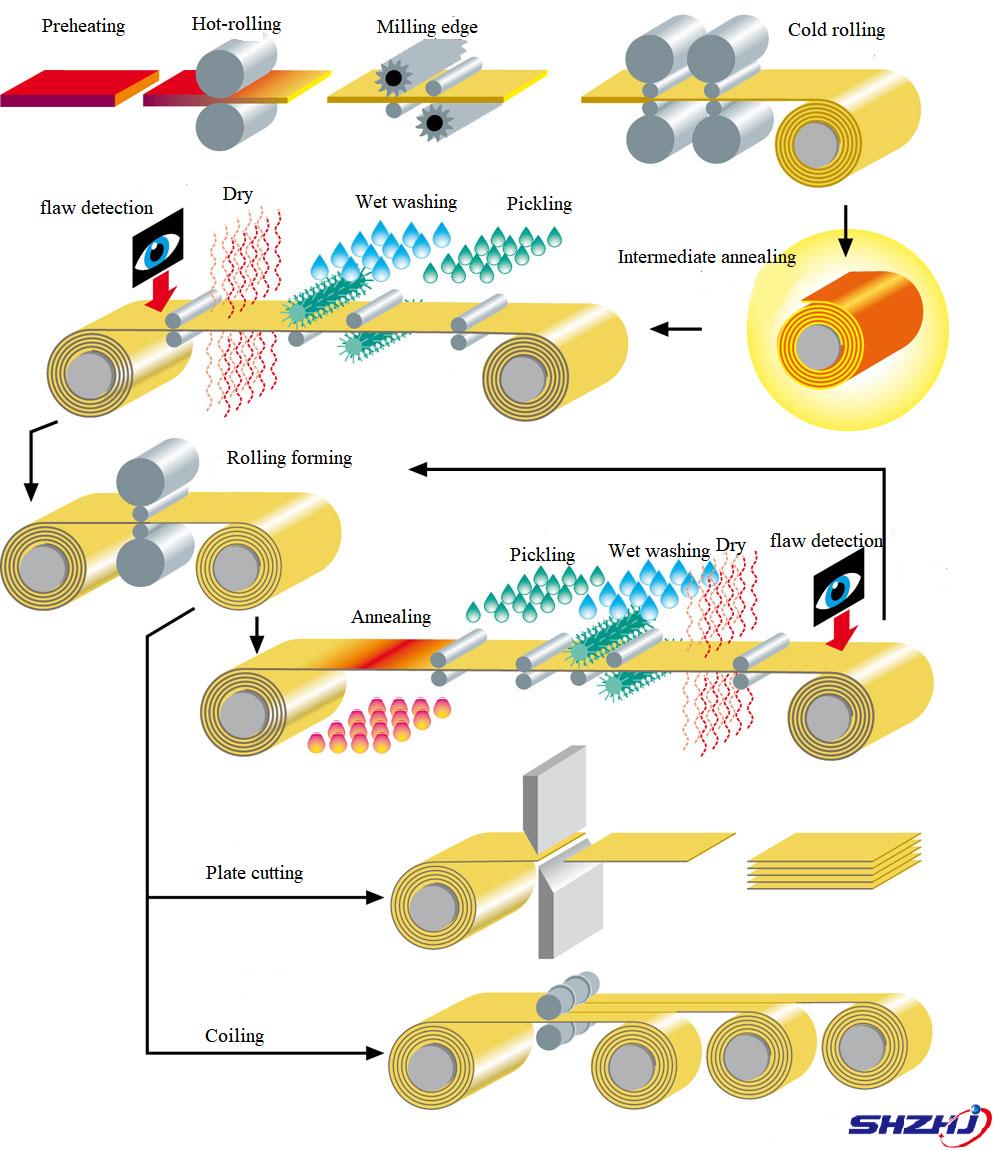

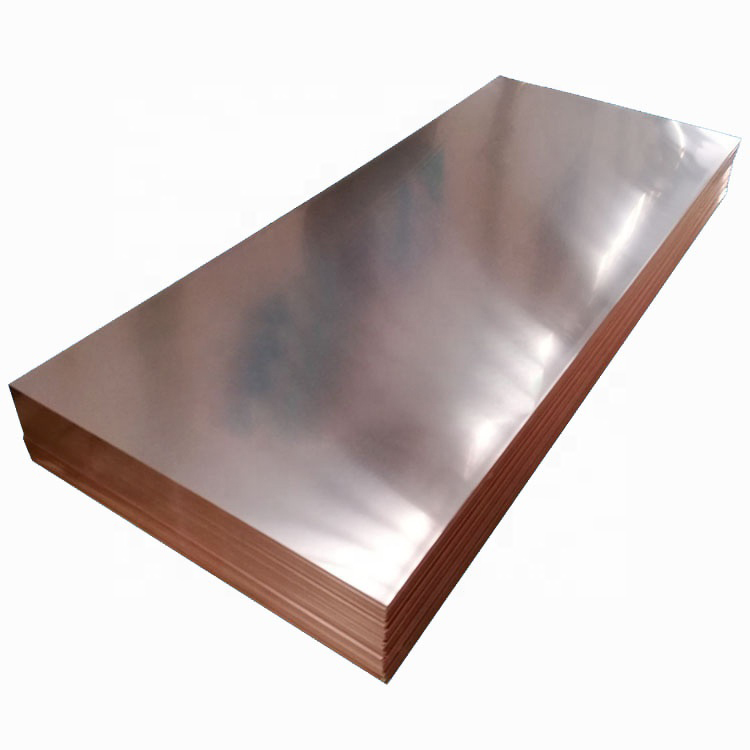

Product detail pictures:

Related Product Guide:

Persisting in "High quality, Prompt Delivery, Aggressive Price", we have established long-term cooperation with clientele from both equally overseas and domestically and get new and old clients' higher comments for Good User Reputation For Copper Backing Plate - Bronze Plates – Rich Stock, Fast Delivery – ZHJ, The product will supply to all over the world, such as: Montreal, Greek, Ukraine, We put the product quality and customer's benefits to the first place. Our experienced salesmen supply prompt and efficient service. Quality control group make sure the best quality. We believe quality comes from detail. If you have demand, allow us to work together to get success.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!

-

2022 China New Design Brass Screen Sheet - Bro...

-

Factory Directly Supply Cheap Factory Price Bra...

-

Hot Sale Factory C27400 CuZn35 H62 Brass Plate ...

-

Factory Supplied Good Quality Pure Copper Plate...

-

Online Exporter Copper Electrical Tape - Coppe...

-

Factory Directly Factory Copper Roofing Sheet -...