Europe Style For Copper Witching Rods - Customize Copper Rod – ZHJ Detail:

1. Extrusion -(rolling) – stretching -(annealing) – finishing – finished products.

2. Continuous casting (lead up, horizontal or wheeled, tracked, impregnated)-(rolling)- stretching -(annealing)- finishing – finished products.

3. Continuous extrusion – stretching -(annealing) – finishing – finished products.

|

Material For Copper Rod |

|

| Copper | C11000, C10200, C12000, C12200 |

| Brass | C21000, C22000, C23000, C24000, C26000, C26200, C26800, C27000, C27200, C28000 |

| Bronze | Phosphor Bronze, Tin Bronze, Aluminum Bronze, Silicon Bronze, Manganese Bronze. |

| Copper nickel alloy | Zinc Copper Nickel, Iron Copper Nickel, etc. |

Copper is a relatively pure copper, generally can be approximated as pure copper. It’s better conductivity and plasticity, but the strength and hardness is ideal.

According to the composition, China’s copper production materials can be divided into four categories: ordinary copper, oxygen-free copper, oxygenated copper and special copper which increase a few alloying elements (such as arsenic copper, tellurium copper, silver copper) . Copper’s electrical and thermal conductivity is second only to silver, and it is widely used in the manufacture of electrically and thermally conductive devices.

Brass rod is a rod shaped object made of copper and zinc alloy, named for its yellow color. Brass rod has good mechanical properties and wear resistance. It is mainly used in the manufacture of precision instruments, ship parts, auto parts, medical accessories, electrical accessories and all kinds of mechanical auxiliary materials, automotive synchronizer tooth rings.

Bronze rod has good electrical and thermal conductivity, good processing and forming performance, and it is widely used in high temperature conductive wear-resistant parts of electrical equipment. Such as motor fairings, collector rings, high temperature switches, electrodes of welding machines, rollers, grippers etc.

Copper nickel alloy rod is a copper alloy with nickel as the main alloying element, which is a continuous solid solution formed by Cu and Ni. Ordinary white copper rod has good corrosion resistance, medium strength, high plasticity and good electrical properties. It can be cold and hot pressure processing. In addition to being used as a structural material, it is also an important high resistance and thermocouple alloy.

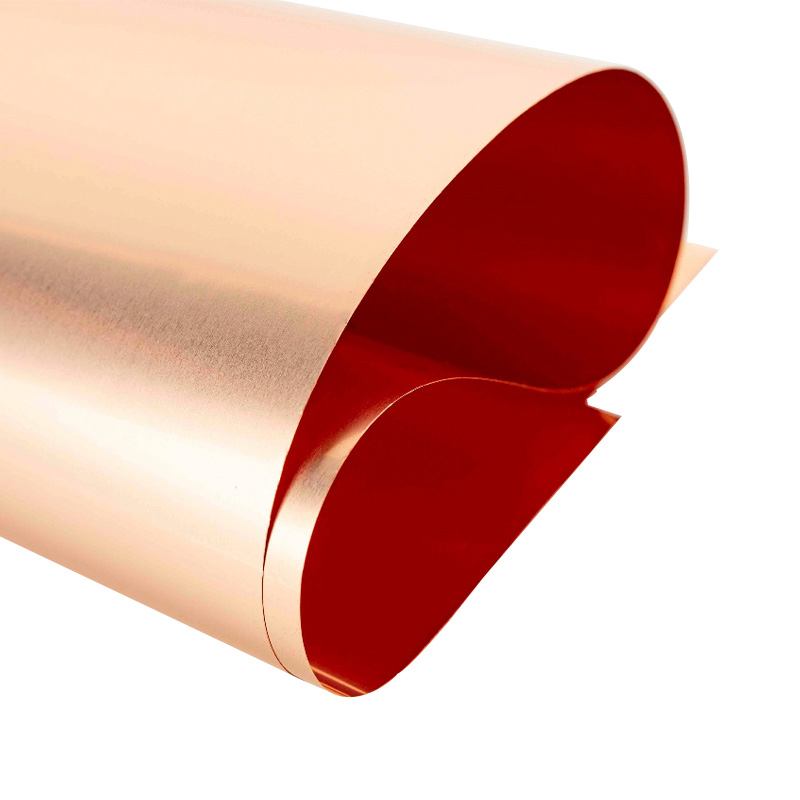

Product detail pictures:

Related Product Guide:

We've been convinced that with joint efforts, the enterprise between us will bring us mutual benefits. We are able to assure you product or service quality and aggressive cost for Europe Style For Copper Witching Rods - Customize Copper Rod – ZHJ, The product will supply to all over the world, such as: Azerbaijan, Burundi, Sudan, They're durable modeling and promoting effectively all over the world. Under no circumstances disappearing major functions in a quick time, it's a should for you of excellent good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the company make a terrific efforts to expand its international trade, raise its company profit and raise its export scale. We're confident that we are going to possess a vibrant prospect and to be distributed all over the world within the years to come.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!

-

Best Price For C5210 Copper Tube - Round and R...

-

2022 Good Quality Threaded Copper Pipe - Coppe...

-

Discountable Price Copper Foil Tape For Slugs -...

-

Rapid Delivery For 25x3mm Copper Tape - Copper...

-

Manufactur Standard Copper Sheet Metal Strips -...

-

Europe Style For Copper Witching Rods - Custom...